Why Essential ERP?

- All-in-One Solution

- Real-Time Tracking

- Enhanced Productivity

- Increased Profitability

- Facilitates Business Growth

- Heightened Customer Satisfaction

- Automated Manufacturing ERP

Gain a Competitive Edge with Cloud-Based Manufacturing ERP – Work Anywhere, Break Boundaries!

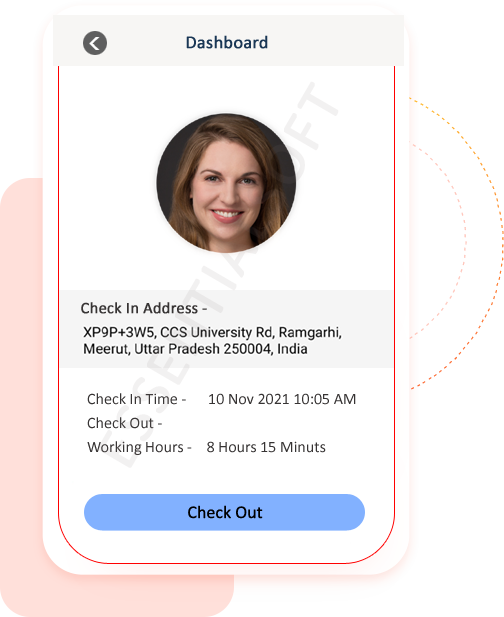

Essential HRMS & Payroll Software: Boost Efficiency, Enhance Performance, and Streamline Decision-Making – All with a User-Friendly Interface. No Need for Complex Infrastructure or High-Tech Implementations – We Simplify Your Payroll Process!

Simplify decision-making for top management with user-friendly Smart Dashboards and centralised data. Boost organisational efficiency in many ways!

Experience streamlined HRMS and Payroll functionalities designed for your convenience.

Efficiently track attendance, streamline processes, and enhance workforce management.

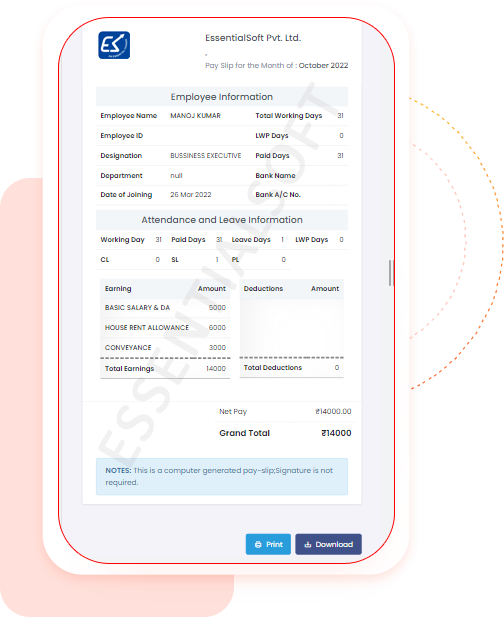

Effortlessly manage payroll, optimise processes, and ensure seamless workforce compensation.

Effortlessly ensure compliance with easy-to-manage processes.

Simplify employee interactions with a user-friendly self-service system.

Enable quick communication with a streamlined text messaging service.

Efficiently handle and oversee assets with ease and precision.

Effortlessly manage batch creation, including MRP and expiry details.

The EssentialSoft ERP Daily Production Register succinctly records key details of daily manufacturing activities for efficient monitoring and analysis.

HRMS and Payroll ERP Software provide significant benefits to organisations by simplifying decision-making for top management through the utilisation of data from Smart Dashboards and centralised databases.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna.